We see a lot of projects where the wrong glass patch fittings cause problems later. When you're working with glass doors, partitions, choosing the right hardware makes all the difference.

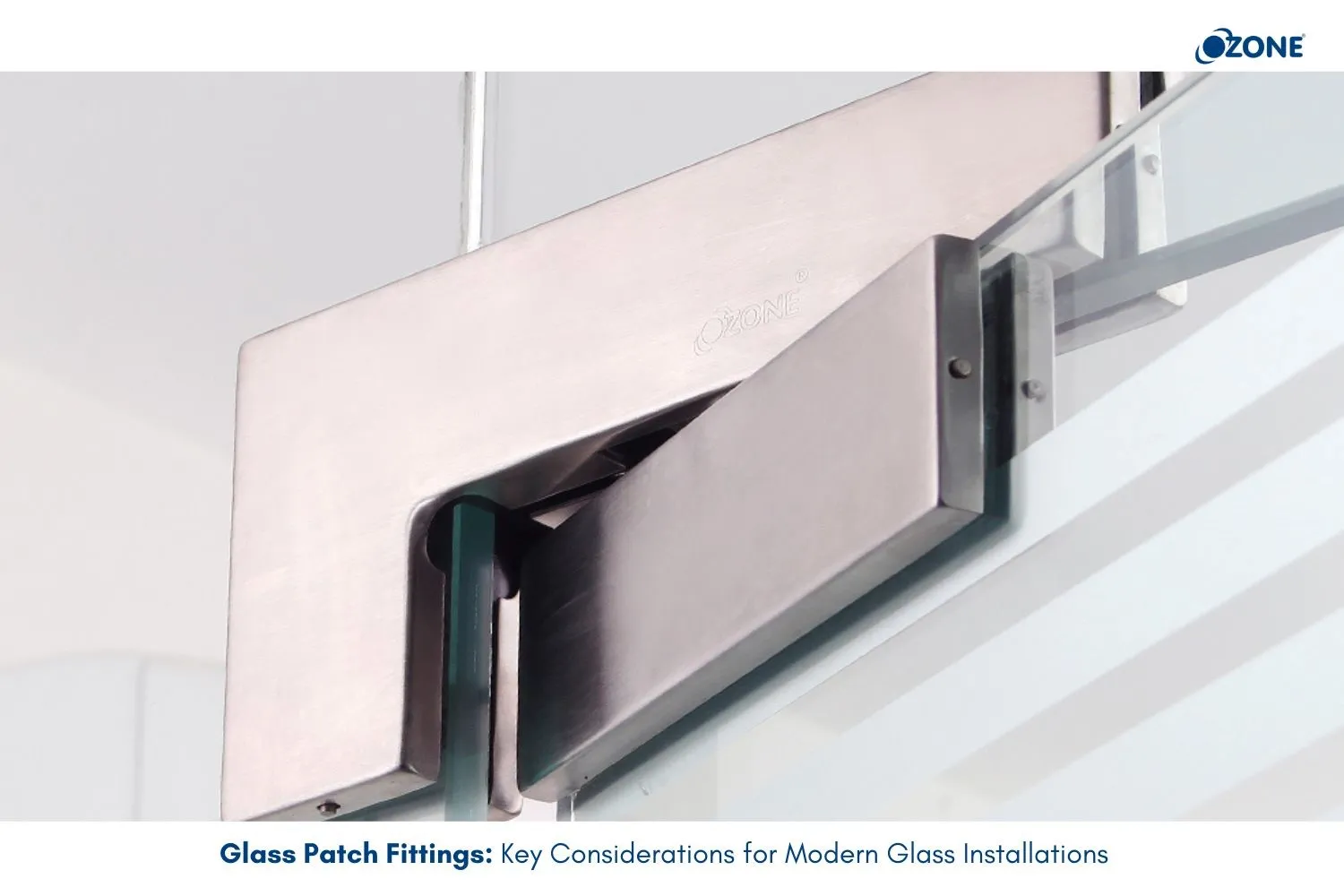

Glass patch fittings hold everything together while keeping the glass as the main focus. Unlike bulky frames, these fittings stay minimal, so your glass installation looks clean and modern.

Here's what we've learned about picking the right patch fitting for fixed glass and avoiding expensive mistakes.

What Makes Glass Patch Fittings Work

Glass patch fittings are the small but critical pieces that connect glass panels to walls, floors, or other glass panels. They provide structural support while maintaining clean sight lines.

The key is that they secure the glass without taking over the design. Good glass-to-glass fitting stays almost invisible while doing its job reliably.

We use Patch Fittings because they've proven themselves in real installations over many years.

6 Things to Check Before Choosing Glass Patch Fittings

Check #1: Load Requirements and Building Codes

Glass patch fittings must handle the actual weight and stress they'll face. We always check the manufacturer's load ratings against the real door weight.

Building codes vary by location and application. Commercial buildings have stricter requirements than residential ones. Patch fitting for fixed glass installations

The Standard Patch Fittings we specify meet international safety standards and work in most commercial applications.

Check #2: Material Quality and Durability

We stick with stainless steel for most projects. It handles weather, humidity, and daily use without problems. Brass looks good but costs more and needs more maintenance.

For coastal or high-humidity locations,

Check #3: Glass Thickness and Type Compatibility

Glass patch fittings come in different sizes for different glass thicknesses. Most handle 8mm to 12mm glass, but some go thicker.

Tempered glass needs different considerations than laminated glass. The patch fitting for fixed glass must grip properly without creating stress points.

We always check compatibility between the glass type and fitting design before ordering. Mismatched components cause installation delays and potential failures.

Check #4: Design Integration and Aesthetics

Glass patch fittings should complement the overall design, not fight it. We match finishes to other hardware in the space.

The Premium Patch Fittings line offers more finish options when the design demands something specific.

Glass to glass fitting hardware is more visible than wall-mounted pieces, so finish quality matters more. Cheap finishes show wear quickly in high-traffic areas.

Check #5: Installation Process and Access

Some glass patch fittings require precise drilling and careful alignment. We factor installation complexity into project timelines.

Patch fitting for fixed glass usually involves structural preparation. The building needs adequate support where the fittings attach.

F

Check #6: Manufacturer Support and Testing

We work with manufacturers who provide proper testing data and technical support. Glass Fittings from Ozone come with load test results and installation guidance.

Good suppliers help solve installation problems and provide warranty coverage. This matters when you're responsible for the project's long-term performance.

Glass to glass fitting applications often need custom solutions. Manufacturers with engineering support can adapt standard products to unusual requirements.

Common Glass Patch Fitting Applications

Office Glass Doors and Partitions

Glass patch fittings in offices need to handle constant use. People push on glass doors differently than they push on wood doors.

We use self-closing patch fitting for fixed glass systems that ensure doors actually close properly. The Self-Closing Patch Fittings eliminate the problem of doors left open.

Retail Storefronts

Retail installations need heavy-duty glass patch fittings because of high traffic and security requirements. The hardware also needs to look good because customers notice it.

Residential Glass Features

Home installations can use lighter-duty patch fitting for fixed glass systems, but they still need proper engineering. We don't compromise on safety even in residential applications.

What We've Learned About Installation

Glass patch fittings work well when they're installed correctly. Poor installation causes most of the problems we see later.

Template drilling ensures accurate hole placement.

We always use the manufacturer's recommended drill bits and installation procedures. Shortcuts during installation cause expensive problems later.

Related Hardware Considerations

Glass patch fittings work with other hardware systems. Glass door spring issues often trace back to mismatched patch fittings and door closers.

Floor springs and glass patch fittings must be compatible. The door hardware guide covers how these systems work together.

Glass to glass fitting installations sometimes need additional support from pivot doors or sliding systems.

Why We Trust Ozone Glass Patch Fittings

We've used Ozone glass patch fittings on hundreds of projects over the years. Their products consistently perform well and their technical support helps solve unusual problems.

The Glass Connectors handle complex glass to glass fitting connections that standard patch fittings can't manage.

When we specify patch fitting for fixed glass systems, we know Ozone products will work as designed. That reliability matters when our reputation depends on the installation working properly.

For technical support on your glass installation project, contact Ozone at customercare@ozone.in, call +91-9310012300, or reach out via WhatsApp for expert recommendations.

FAQ

What's the difference between standard and premium glass patch fittings?

Standard fittings handle most commercial applications with basic finishes. Premium fittings offer more finish options, higher load ratings, and better corrosion resistance.

How do I know what load rating I need for my glass door?

Calculate the total door weight including glass and frame. Add 50% safety margin and check manufacturer specifications. Most office doors need 80-100kg rated fittings.

Can patch fittings work with any glass thickness?

No. Each fitting is designed for specific glass thickness ranges. Most handle 8-12mm glass, but verify compatibility before ordering.

What's the best material for coastal installations?

Use 316-grade stainless steel for coastal areas. The extra corrosion resistance prevents problems from salt air and humidity.

Do glass to glass fittings need special installation tools?

Yes. You need diamond-tipped drill bits, alignment templates, and proper torque specifications. Poor installation tools cause the most fitting failures.

How often do patch fittings need maintenance?

Good quality stainless steel fittings need minimal maintenance. Clean them regularly and check mounting screws annually. Replace any fittings showing wear or corrosion damage.

Glass Fittings